- Home

- Services

- Operational Transformation

- Quality Transformation

- Robotic Services

- Surface Treatment Process Plant

- Product Cost Actualization

- Operational MIS Preparation

- Maintenance Management

- Lean Manufacturing

- Inventory Management

- TPM Implementation

- Energy Saving Solutions

- Project Management

- Packaging Solutions

- System Implementation & Audits

- HR Services

- Technical and Behavioral Trainings

- Neuro Linguistic Programming ( NLP )

- Cultural Improvement Program

- Re – Programming of Sub Conscious Mind

- Management Through Bhagwat Gita Principles

- Emotional Intelligence

- Environment Social Governance

- Merger & Acquisition

- Technical Training

- Soft Skill Training

- About

- Contact

- Consultant Onboarding

- Home

- Services

- Operational Transformation

- Quality Transformation

- Robotic Services

- Surface Treatment Process Plant

- Product Cost Actualization

- Operational MIS Preparation

- Maintenance Management

- Lean Manufacturing

- Inventory Management

- TPM Implementation

- Energy Saving Solutions

- Project Management

- Packaging Solutions

- System Implementation & Audits

- HR Services

- Technical and Behavioral Trainings

- Neuro Linguistic Programming ( NLP )

- Cultural Improvement Program

- Re – Programming of Sub Conscious Mind

- Management Through Bhagwat Gita Principles

- Emotional Intelligence

- Environment Social Governance

- Merger & Acquisition

- Technical Training

- Soft Skill Training

- About

- Contact

- Consultant Onboarding

TPM Implementation

TPM Implementation

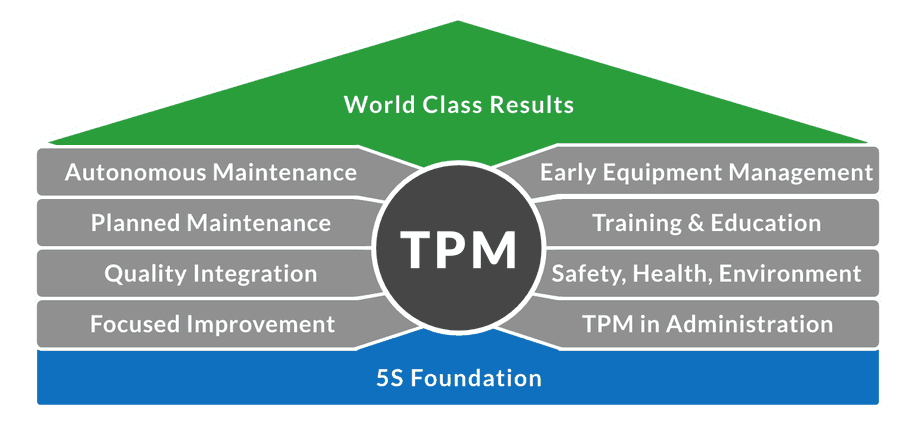

Our consultancy helps organizations integrate TPM principles, enhancing equipment reliability and engaging

employees at all levels to drive operational excellence and achieve sustainable productivity gains.

Structured phases of TPM Implementation

Declaration by Top Management

Education & Training

Employees are trained on TPM principles and methodologies.

Formation of TPM Committee

A dedicated team is established to drive TPM initiatives.

Setting Basic TPM Principles & Targets

Defining clear goals for productivity, maintenance, and efficiency.

Preparation of a Master Plan

Developing a roadmap for TPM implementation.

Kickoff of TPM

Official launch of TPM activities across departments.

Establishment of Production Efficiency Systems

Implementing strategies to improve equipment effectiveness.

Initial Control System for New Equipment

Ensuring new machinery is designed for easy maintenance.

Quality Maintenance Systems

Integrating quality control measures into maintenance processes.

Efficiency Improvement in Administration & Other Departments

Expanding TPM beyond production to all business areas

Safety, Health & Environmental Control

Embedding safety and sustainability into TPM practices

Complete Implementation & Continuous Improvement

Sustaining TPM through ongoing refinements and optimizations

Structured phases of TPM Implementation

- 1. Declaration by Top Management

- 2. Education & Training – Employees are trained on TPM principles and methodologies.

- 3. Formation of TPM Committee – A dedicated team is established to drive TPM initiatives.

- 4. Setting Basic TPM Principles & Targets – Defining clear goals for productivity, maintenance, and efficiency.

- 5. Preparation of a Master Plan – Developing a roadmap for TPM implementation.

- 6. Kickoff of TPM – Official launch of TPM activities across departments.

- 7. Establishment of Production Efficiency Systems – Implementing strategies to improve equipment effectiveness.

- 8. Initial Control System for New Equipment – Ensuring new machinery is designed for easy maintenance.

- 9. Quality Maintenance Systems – Integrating quality control measures into maintenance processes.

- 10. Efficiency Improvement in Administration & Other Departments – Expanding TPM beyond production to all business areas

- 11. Safety, Health & Environmental Control – Embedding safety and sustainability into TPM practices

- 12. .Complete Implementation & Continuous Improvement – Sustaining TPM through ongoing refinements and optimizations